TMS (The Minerals, Metals, & Materials Society) held their annual conference from February 27th to March 3rd 2022, at the Anaheim Convention Center & Anaheim Marriott in Anaheim, CA. This year’s TMS conference marked the 150th conference held by the organization, which has been in existence since 1871.

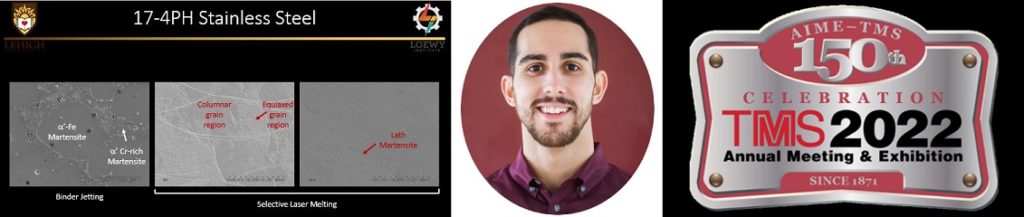

Loewy Institute Graduate Researcher Michael Pires attended TMS2022 and presented his research, Challenges Associated with Standard and Micro-Additive Manufactured 316L and 17-4PH Stainless Steel Components Produced by Binder Jetting, Digital Light Processing, and Selective Laser Melting.

Michael’s research examined the microstructural differences and mechanical performance between two stainless steel alloys (316L and 17-4PH) printed using varied additive manufacturing processes. Binder jetting, for example, is a print and sinter based technology, while selective laser melting is categorized as powder-bed laser fusion. Although additive manufacturing technologies continue to improve, printing components with micron-sized features is still a challenge. Michael utilizes electron microscopy (SEM, XEDS, EBSD), x-ray diffraction (XRD), and mechanical testing (tensile and micro-indentation), among others, to evaluate these components at both standard and micro-scales.

Future research performed by Michael on this topic will involve conduction of tensile testing of these materials as well as additional material characterization.