This week I continued my research by looking at electrodeposition in ionic liquids, as well as different grinding processes for PCBs. I was also able to search for more companies, authors, and researchers to contact in order to learn more about specific processes.

My research with ionic liquids continued from last week, with a focus on electrodeposition this week. Electrodeposition is the process of putting a metal coating onto conductive materials through an electric current. Some benefits of using this method include its efficiency for objects with complex shapes, high conductivity, low viscosity, and high solubility to metal salts. This is a method I plan to continue researching next week as well.

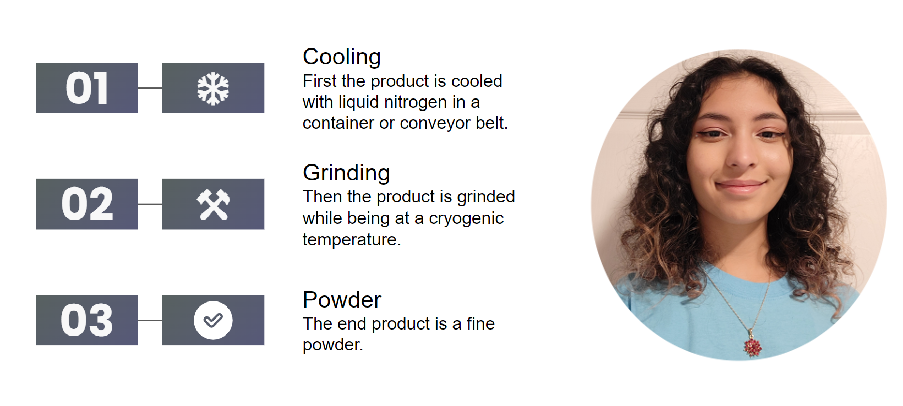

I have also looked into cryogenic grinding processes for lithium-ion batteries. I chose to look into this process for lithium-ion batteries since they have become critical resources for various technologies, including electric vehicles. From what I read on cryogenic grinding, using low temperatures improved the peel-off efficiency significantly. Comparatively, I also studied the grinding processes without low-temperature conditions. I examined cryogenic and high-temperature grinding for PCBs as well as lithium-ion batteries.

This week I continued to contact various companies and individuals to set up meetings in order to learn more about E-waste recycling and some specific methods others have used. The companies I have contacted include: Umicore, Elemaster, and Cohen. I have also reached out to three individuals who previously did research that aligns with our interests and was able to set up a meeting with one of them for Tuesday, June 27th, 2023. Because of all the contacts we currently have pending, I updated the contact list in order to ensure organization.